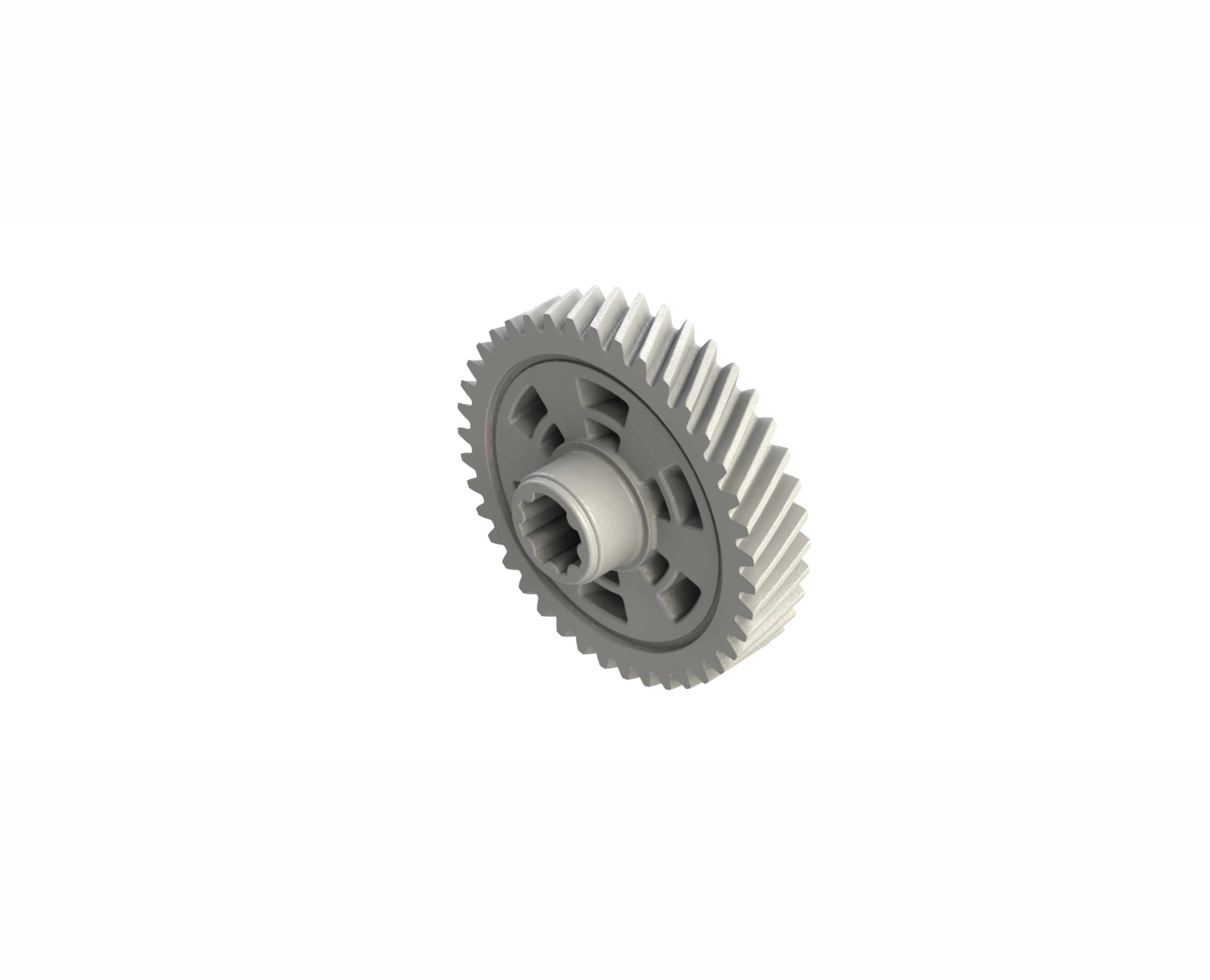

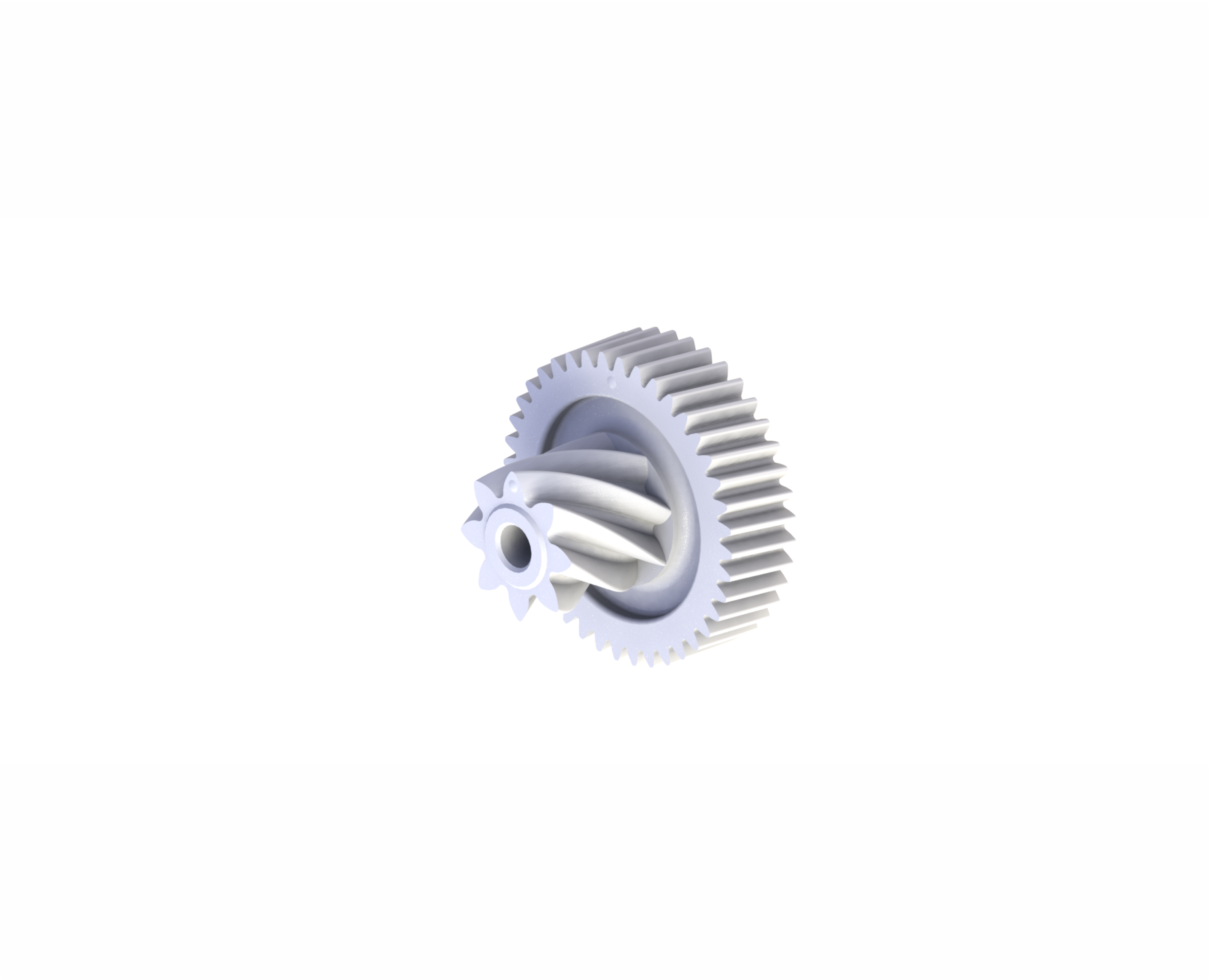

Gears

These models were created when I was working at Titanic Plastic Inc. as a design engineer. Here, gears rotate forward and backward during car seat adjustment. To control costs, the following parts were made in plastic for bulk production. Window gears were 47-mm in diameters and had 40 teeth; they are shown in a 3D model (Fig. 1-1). Parts made with POM polymer, are shown in Fig. 1-2. Spiral gears have spiral cogs, as shown in 3D model (Fig. 2-1), and parts made with POM polymer are shown in Fig. 2-2. These models were dicult to build. In addition to rotation functionality, they needed enough strength and correct cog shapes to minimize noise when they are rotating.

Fig.1-1

Fig.2-1

Fig.1-2

Fig.2-2

POM: polyxymethylene

(All the images displayed in this section were permitted by Titanic Plastic Inc., although the measurements were truncated to protect the copyrights of the company).

Cell

(+44) 77-515-80914Address

17 Forteath St.,Elgin Moray, Scotland IV30 1PN